(Seamless / Welded)

• Elbow – 45°, 90°, 180° RL – SR

• Elbow – 1D, 1.5D, 3D, 5D

• Tee – Equal, Straight, Reducing

• Cross – Equal, Reducing

• Reducers – Concentric, Eccentric

• Stub End, Lap Joint End

• Pipe Cap, End Cap

• Collar, Lateral

(Seamless / Welded)

• Elbow – 45°, 90°, 180° RL – SR

• Elbow – 1D, 1.5D, 3D, 5D

• Tee – Equal, Straight, Reducing

• Cross – Equal, Reducing

• Reducers – Concentric, Eccentric

• Stub End, Lap Joint End

• Pipe Cap, End Cap

• Collar, Lateral

(Forged)

• Elbow – 45°, 90°, 180°

• Tee – Equal, Reducing

• Cross – Equal, Reducing

• Coupling – Half, Full

• Cap -End Cap

(Forged)

• Elbow – 45° Elbow, 90° Elbow, 180° Elbow

• Tee – Equal, Reducing, Lateral

• Cross – Equal, Reducing

• Coupling – Full, Half

• Cap – End Cap

• Bushing

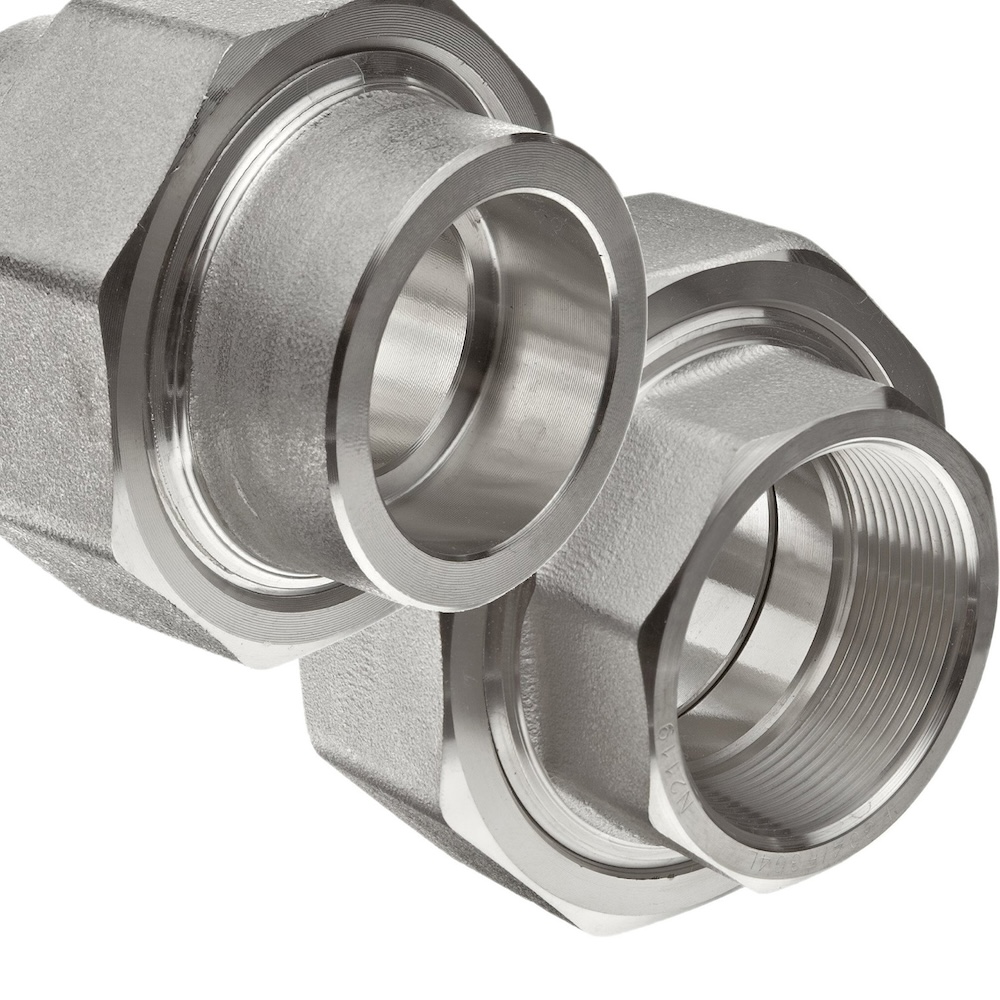

• Union

• Plug

Body Material: Butt weld fittings are made from different body materials, including alloy, stainless, carbon steel and nickel alloys. They are typically manufactured using welded or seamless pipes as the starting material.

Ends treatment: All butt weld fittings have beveled ends in accordance with ASME B16.25 standards. This allows for full penetration without the need for additional preparation.

The dimensions: Butt-weld pipe fittings are based on the pipe dimensions standard ANSI B36.10 and B36.19.

Diameter range: 1”, 2”, 3”, 4”, 6”, 8” and up to 96”.

Thickness range: Schedule 10, schedule 40, schedule 80, XS, XXS and SCH 160

Body Material: Socket weld fittings are made from different body materials, including Stainless steel, duplex steel, alloy steel and carbon steel. They are typically manufactured using forging of metals.

Ends treatment: Most socket weld fittings have plain ends in accordance with ASME B16.11 standards. These types of connections are socketed so as to have a plain spigot end of the pipe.

The dimensions: Socket weld pipe fittings are based on the pipe dimensions standard ANSI / ASME B 16.11.

Diameter range: ¼”- 4”.

ASME B16.11 and BS3799 standard specification, which covers pressure Class 3000lb, 6000lb and 9000lb

Body Material: Forged threaded fittings are made from different body materials, including Stainless steel, duplex steel, alloy steel and carbon steel. They are typically manufactured using forging of metals.

Ends treatment: All threaded fittings fittings have threaded end in accordance with ASME B16.11 standards. These types of connections are used for piping applications where pipes have smaller bore and diameter.

The dimensions: Socket weld pipe fittings are based on the pipe dimensions standard ANSI / ASME B 16.11.

Diameter range: ¼”- 4”.

ASME B16.11 and BS3799 standard specification, which covers pressure Class 3000lb, 6000lb and 9000lb

| Material type | Standard Specifications | Grades |

| Carbon Steel | A234, A860 | A234 WPB / A860 – MSS-SP-75 WPHY 42, 46, 52, 56, 60, 65, 70 |

| Carbon Alloy Steel – Low Temp | A/SA420, A/SA350 | Gr WPL3, Gr WPL6 |

| Chrome Moly Alloy | A234 / SA234, A182 / SA182 | P11, P22, P5, P9, P91 Type 1 & 2, P92 |

| Stainless Steel | A403/ SA403, A182 / SA182 | TP304, TP304/H/L, TP310, TP310S, TP316, TP316H/L, TP317L TP321, TP321H, TP347, TP347H |

| Duplex – Super Duplex Steel | A/SA815, A/SA182 – F50, F51, F60, F61, F53, F55 | 2205, 2507 |

| Nickel 200-201 | B/SB366, B/SB564 | 200, 201 |

| Alloy 20 | B/SB366, B/SB462, A/SA182 | 20 |

| Monel® 400 | B/SB366, B/SB564 | 400 |

| Inconel® | B/SB366, B/SB564 | 600, 625 |

| Incoloy® | B/SB366, B/SB564 | 800, 800H/HT, 825 |

| Hastelloy® | B/SB366, B/SB564 | B, B2, B3, C-276, C-4, C-22, G, G2, G3, X |